UHMW-PE Welding

Plastek Werks developed a process for welding complex angles of UHMW-PE in a wear application for a major clothing manufacturer.

A proprietary process unique to the manufacturer’s product was destroying stainless steel equipment, and continual replacement became a major cost factor for production. In trials, the manufacturer employed numerous alternatives ranging from ceramic coatings to various lining systems to extend the life of the stainless steel equipment. Some of these trials failed within hours of use.

A proprietary process unique to the manufacturer’s product was destroying stainless steel equipment, and continual replacement became a major cost factor for production. In trials, the manufacturer employed numerous alternatives ranging from ceramic coatings to various lining systems to extend the life of the stainless steel equipment. Some of these trials failed within hours of use.

Our welded UHMW-PE lining with extrusion welded seams out-performed every other lining material that was tested over a three-month period.

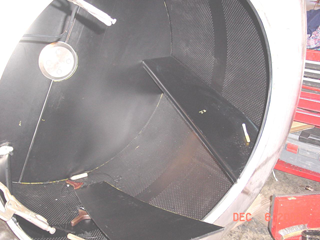

The UHMW-PE welded assembly consisted of CNC machining of .375” thickness plate materials along with heat forming of various internal veins that were integral parts of the process function. Extrusion welding completed the lining system so that the entire assembly became one UHMW lining system. We performed CNC machining and heat forming in our shop, with installation and final assembly, including welding, completed at the customer’s facility.

For more information about our plastic welding or any of our other products and services, please call us toll-free at 1.888.675.2783.