Concrete Protective Liners

Applications

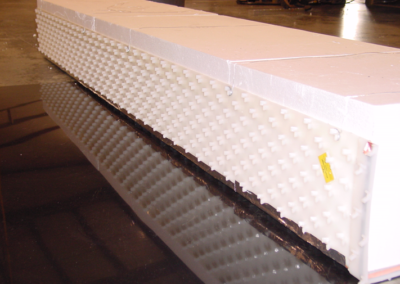

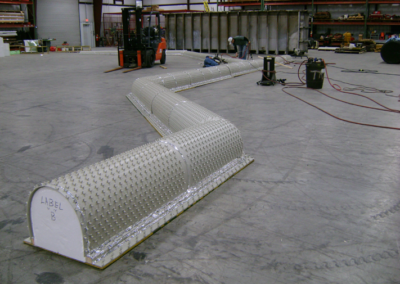

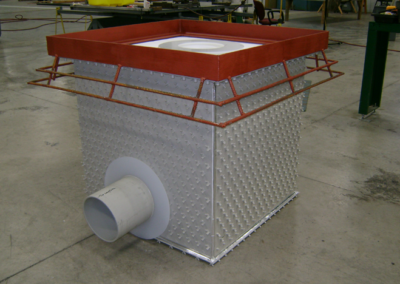

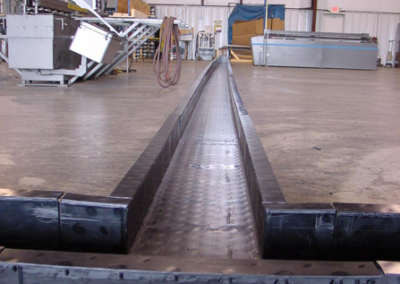

ACROLINE® Concrete Protective Linings outperform traditional coatings and traditional linings in aggressive acid and caustic environments. ACROLINE® Systems are a suite of thermoplastic semi-finished products, which are welded or fused together to form custom-designed single or dual layer liners for concrete structures. This type of lining provides a chemical-resistant, leak-tight barrier to contain environmentally hazardous materials or to protect concrete structures from chemical attack. The anchored concrete protection liners are mechanically locked into a cement substrate to resist thermal expansion and contraction and groundwater pressure. The high elongation of thermoplastics and mechanical anchoring system of the ACROLINE® concrete protection liner allows the liner to bridge cracks in the substrate. Some areas of use for ACROLINE® concrete protective linings are:

- Containment Areas

- Flooring Systems

- Trenches

- Sumps

- Foundations

- Manholes and Lift Stations

- Process Vessels

- Sewer Pipe Rehabilitation

- Storage Tanks

Advantages

- Mechanically anchors into concrete

- New lining can be placed into chemical service immediately after welding – No 28-day cure required, as with coatings

- Ideal for new construction or where retrofits are needed

- Works in conjunction with standard concrete practices

- Meets EPA requirements for dual containment with leak detection system

- Liner bridges cracks in concrete substrate, maintaining containment and corrosion protection

- Superior chemical resistance

- Anchored sheet is manufactured in a single process with no interface between the anchors and the sheet

- Liner system has a long design life and is maintenance-free and repairable

- Dual-wall ACROLINE® System liner provides integral secondary containment and leak monitoring capability

- Provides a continuous system when welded to piping of same resin

- Can be prefabricated and preformed

- Trench systems can also be fabricated to any size or shape to provide a positive tie-in with flooring systems

- A variety of thicknesses and plastics are available to meet your thermal and chemical resistance requirements